Product Introduction: Blended Yarn T/C (Polyester/Cotton) Ring Spun Yarn

Blended T/C (Polyester/Cotton) Ring Spun Yarn is a versatile and durable yarn made by combining polyester and cotton fibers through traditional ring spinning technology. This blend harnesses the best qualities of both fibers — the strength and wrinkle resistance of polyester with the softness and breathability of cotton.

Widely used across the textile industry, T/C ring spun yarn offers excellent performance, cost-efficiency, and a smooth finish, making it a preferred choice for a variety of woven and knitted applications including shirts, uniforms, bedding, and casualwear.

Key Features:

Composition: Polyester/Cotton blend (customizable ratios, e.g., 65/35, 80/20)

Spinning Method: Ring spun for superior yarn structure

Soft hand feel with good strength and durability

Easy to dye and finish

Suitable for both weaving and knitting

Cost-effective with excellent dimensional stability

Whether you need consistency for large-scale production or performance for finished garments, our T/C Ring Spun Yarn is a dependable solution for modern textile needs.

Style :

NE 30/1 Polyester 65% Cotton 35% (TC 65/35) Blended Spun Yarn Raw WhiteGrade :

AAHS Code :

5510300000Twist :

Z twistPayment :

TT,LC at sightColor :

Raw WhiteLead Time :

7-15daysBlended yarn T/C (polyester/cotton) ring spun yarn refers to a type of yarn that is made by combining polyester and cotton fibers through ring spinning technology. This type of yarn is popular in the textile industry due to its durability, flexibility, and affordability.

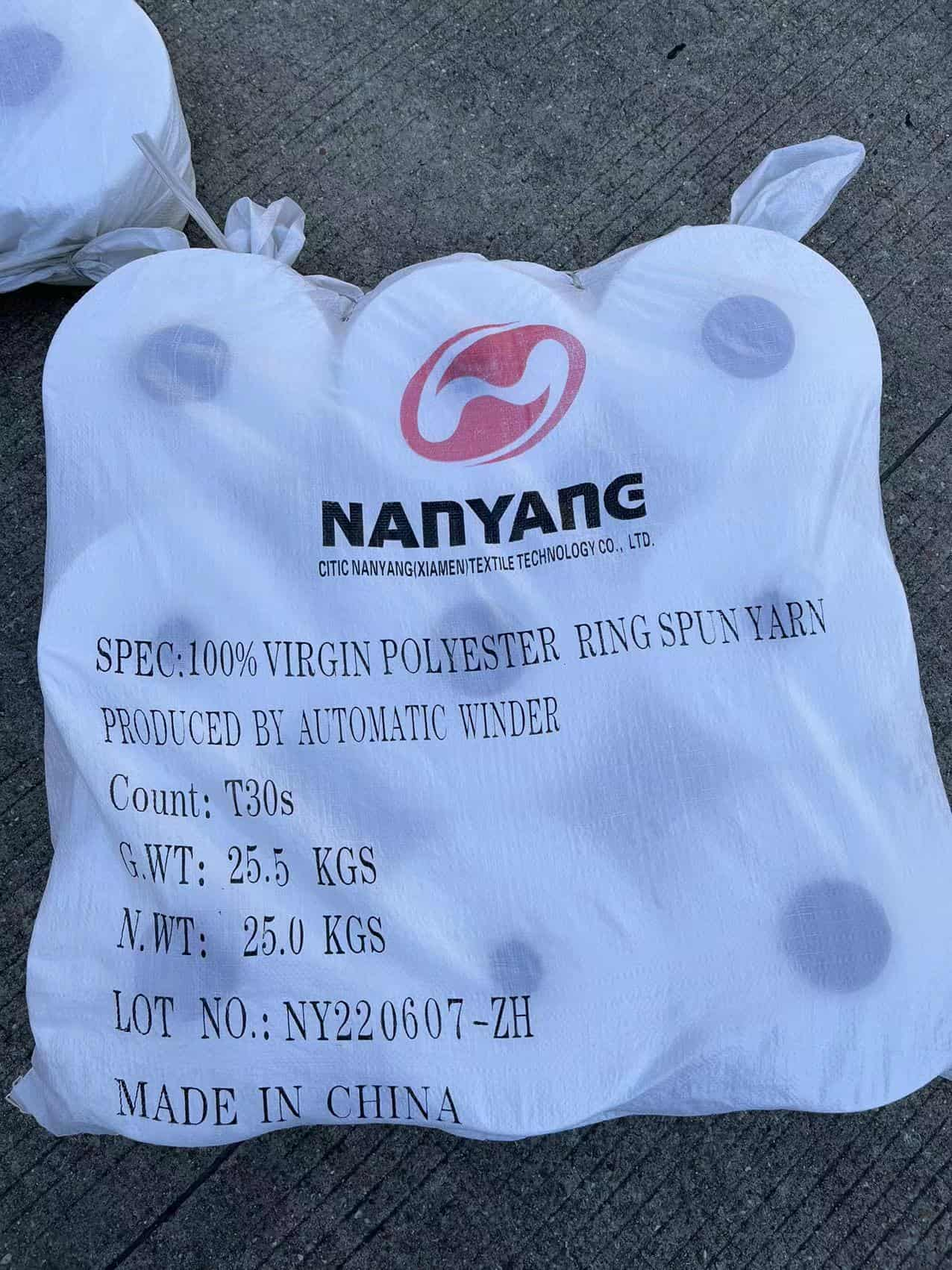

As famous China polyester spun yarn mill,NANYANG have one hundred and seventy thousand spindles.Daily output is probably one hundred tons.We have enough capacity to supply.NanYang polyester yarn is available in different counts, the yarn count can range from 21s to 40s.

| PRODUCT LIST | |||||

| POLYESTER/COTTON SPUN YARN | 100% VIRGIN | T/C 85/15 NE21S/1 | R W | ||

| POLYESTER/COTTON SPUN YARN | 100% VIRGIN | T/C 85/15 NE32S/1 | R W | ||

| POLYESTER/COTTON SPUN YARN | 100% VIRGIN | T/C 85/15 NE40S/1 | R W | ||

| POLYESTER/COTTON SPUN YARN | 100% VIRGIN | T/C 65/35 NE21S/1 | R W | ||

| POLYESTER/COTTON SPUN YARN | 100% VIRGIN | T/C 65/35 NE26S/1 | R W | ||

| POLYESTER/COTTON SPUN YARN | 100% VIRGIN | T/C 65/35 NE30S/1 | R W | ||

| POLYESTER/COTTON SPUN YARN | 100% VIRGIN | T/C 65/35 NE40S/1 | R W | ||

Product Specification

The product specifications of T/C (polyester/cotton) blended yarn can vary depending on the specific needs of the end-user.

Polyester cotton yarn 65/35 is a popular blend of two fibers, polyester and cotton, where polyester make up 65% and cotton make up 35%.

Features:

Strong and durable : Polyester is a synthetic fiber that is known for its strength and durability. Combined with cotton, the yarn becomes strong and long-lasting.

Breathable : The cotton fibers in the blend allow air to circulate through the fabric and making it comfortable to wear .

Soft : Polyester cotton yarn 65/35 is comfortable to wear and has a soft feel.

Easy care : The blended yarn is machine washable and dryer friendly.

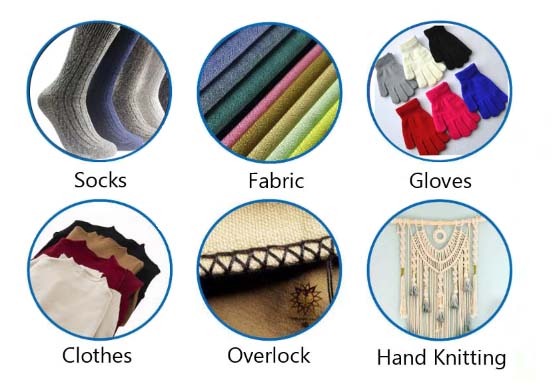

Product Application

NanYang spun polyester yarn is used for knitting & weaving fabrics. it is workable for 28 gauge knitting machine and water jet loom,airjet loom. It is also used for manufacturing of sewing thread and embroidery yarn.

Packing and Shipping

Bag packing:

2.78kgs/cone, 9cones/25kgs/bag, 960bags/24000kgs/40Q

2.08kgs/cone, 12cones/25kgs/bag, 960bags/24000kgs/40Q

Cartons packing:

2.08kg/cone, 33.28kgs/carton, 600cartons/19968kgs/40HQ

FAQ

1.What is mainly used for POLYESTER COTTON YARN 65/35?

This type of yarn is mainly used for making a wide range of clothing items such as shirts, blouses, dresses, and skirts. It is also used in the production of bed sheets, pillowcases, and other home textiles.

2.What are the specifications of cotton yarn?

Knitting yarns require small twists and even yarns to ensure thick piles, good elasticity and strong warmth retention of knitted sweaters. The yarn for weaving is required to be light, the weft yarn is less knotted, and the evenness.

3.What is the cause of dust on the equipment?

The problems about dust in the equipment usually occur in the recycled yarns.

The main reasons are the problem of raw materials, too much hairiness of yarn and too low humidity in the workshop, and so on.

At present, our products rarely have such a situation.

Tags :

Get the latest recycled fiber trend in your inbox.